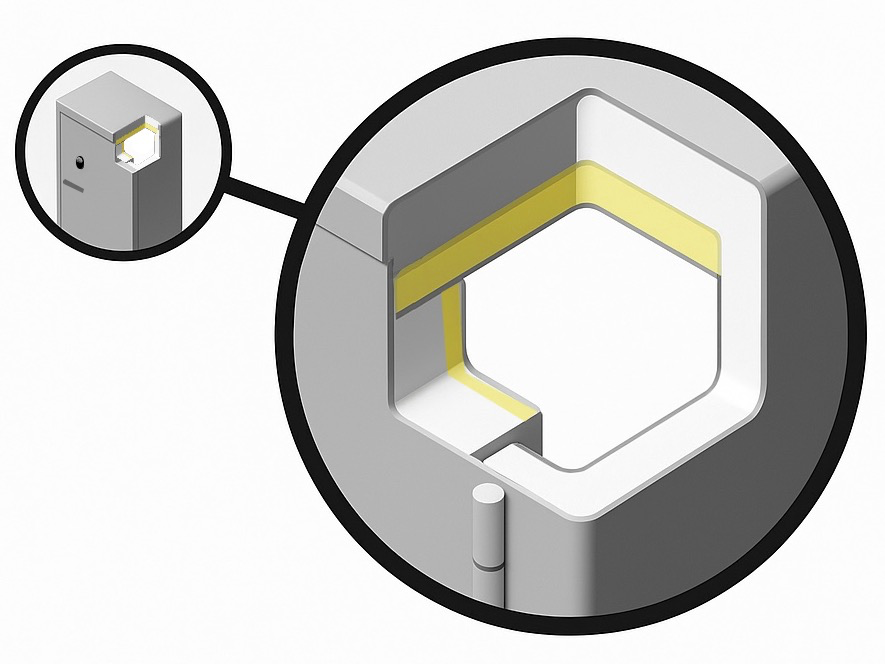

Up to 4.5"of 2300° Ceramic Wool & Glass Blanket

2.5" 2300° Ceramic Wool

2.5" applied seamlessly to the entire interior.

3/8" Solid Door Plate

2" Glass Blanket

2" is applied to the top and bottom of the safe, while 1" is applied to the door.

4 Gauge Body

Nearly 1/4" thick.

16 Gauge Steel Liner

Fully encases the entire interior.

Sturdy Gun Safe builds every fire-lined gun safe with 2300°F-rated, 8 lb. density ceramic wool and glass blanket insulation—the same high-performance materials used to contain heat in industrial ovens and kilns. We feature 2 1/2" of ceramic insulator compressed (with a 16g liner) to 2 1/4" for the right, left, back wall, and door jambs. This prevents the material from shaking downward. The top and bottom will have 2.5" of ceramic insulator and 2" of glass blanket. The door will have 2.5" of ceramic insulator and 1" glass blanket. This premium insulation combination is engineered to block heat, not just resist it, maintaining its structure even after exposure to fire. Unlike common alternatives such as drywall or low-density materials, ceramic insulation won’t crumble, separate, or lose integrity—and it fits tightly into every crevice without open seams. The included 16-gauge interior liner also reinforces shelving, offering a sturdier and more secure interior compared to competitors that rely on weak Sheetrock and thin felt liners. With this advanced construction, it’s no surprise that Sturdy Gun Safe stands among the most fire-resistant safes on the market today.

Our fire-lined safes feature a UL-tested intumescent fire caulking sealed with a custom-fit boiler gasket, designed for extreme-heat ovens and kilns. The LCI Firestop Sealant prevents the spread of fire, smoke, and moisture for up to 3 hours, expanding to eight times its size under heat. Our boiler gasket is twice as wide as the average competitor’s, offering 2× better coverage and protection. A precision-fit gasket is essential because no two door clearances are exactly alike. Competitors often use one-size-fits-all Palusol gaskets, which require heat to expand before sealing—leaving gaps vulnerable to fire penetration.